Description:

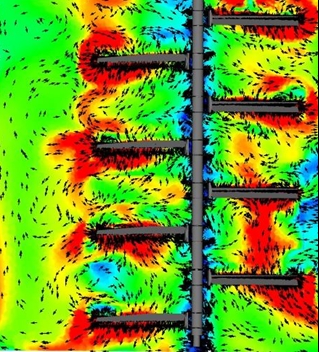

We develop, construct, manufacture, deliver and assemble for you a custom-built biogas mixer. The mixer blades are calculated and designed according to our mathematical simulations, as in the above pictures. The mixer blades are designed to reach a maximum circulation at best energy efficiency. These types of mixers are able to handle very big tank volumes. It generates huge energy inputs into the tank, which allows circulating the complete tank volume repeatedly, at all levels.

Due to our special friction-free bearing system, the energy is use for the circulation process. Besides, our bearing system prevents blocking by small stones or other solid particles, due to its design.

The above picture shows our new mixer with a 10 m diameter tank. Furthermore, a height of 8 m and fitted with 10 mixer blades. The mixer can be installed on the brink of the tank. However, the distance from the tank wall to the middle of the mixer shaft should not be less than 2,5 m. The best mixing result will be achieved if the mixer is installed close to the middle of the hydrolysis tank. This mixer generates a speed of approximately up to 2 meter/sec inside the tank, which is illustrated in red. Due to this high speed, the sedimentation of sand or other small particles can be reduced or avoided. At the same time, the mixer destroys floating sludge blankets and reduces or totally prevents new floating sludge blankets. Due to the complete mixing, at all levels, the mixer enables the maximum release of biogas.

Application:

This mixer is designed to be used in hydrolysis tanks, for circulating the complete hydrolyse

tank volume. This mixer is perfectly designed to be used even if the biomass level inside the tank is fluctuating. The mixer is calculated and designed for a medium TS (total solid) content of about 8 %. A maximum TS (total solid) content of 15% will be possible.

Important Note:

Due to especially calculated mixer blades and therefore huge energy inputs into the hydrolysis tank, the complete hydrolysis-tank volume is circulating. In opposite to the conventional paddle-mixers, which are only able to mix the biomass inside its own paddle-arm-radius. The universal-intermix UD-Mixer are designed for a medium TS (total solid) content of about 8 %, maximum up to 15% possible.

Special Benefits:

- Individual implementation according to our customer’s requirements.

- Complete calculation and dimensioning according to our customer’s requirements.

- Sedimentation

- Floating sludge blankets can be reduced or totally prevented

- Due to especially calculated mixer blades and therefore huge energy inputs into the hydrolysis tank, the complete hydrolysis-tank volume is circulating. In opposite to the conventional paddle-mixers, which are only able to mix the biomass inside its own paddle-arm-radius.

- Designed for a medium TS (total solid) content of about 8 %, maximum up to 15% possible.

- The mixer is equipped with a strong gearbox motor, frequency controlled. Especially during the starting phase of the mixer the power consumption is very high. This power will be supplied by the frequency converter. After the mixer is running, the power consumption can be individually reduced by reducing the speed, depending on the biomass and TS-content.

The following materials are available:

- Steel-galvanized or coated

- Typical stainless steels (s.s) like s.s. 304 or s.s. 316 / s.s. 316 Ti

- For special requirements we can even offer special materials

The following options are available:

- R-UD-6= mixer with 6 mixer blades for tanks of 6 m depth and a diameter of 8-10 m

- R-UD-8= mixer with 8 mixer blades for tanks of 6 m depth and a diameter of 8-10 m

- R-UD-10= mixer with 10 mixer blades for tanks of 8 m depth and a diameter of 8-10 m

English (UK)

English (UK)  Deutsch

Deutsch