Description:

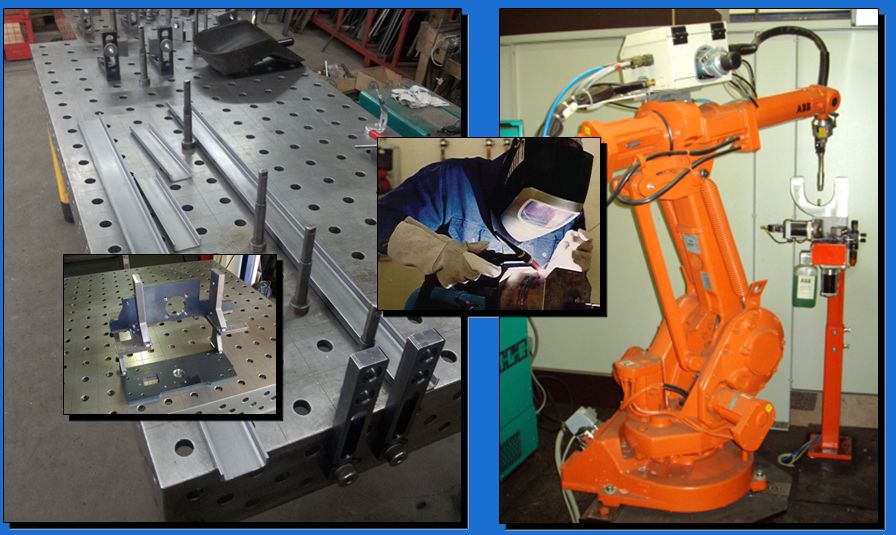

Small and midium size products are manufactured on special welding-clamping tables. Because, on those working-tables the products can be adjusted and fixed exactly to achive perfect measurements according to the required drawings.

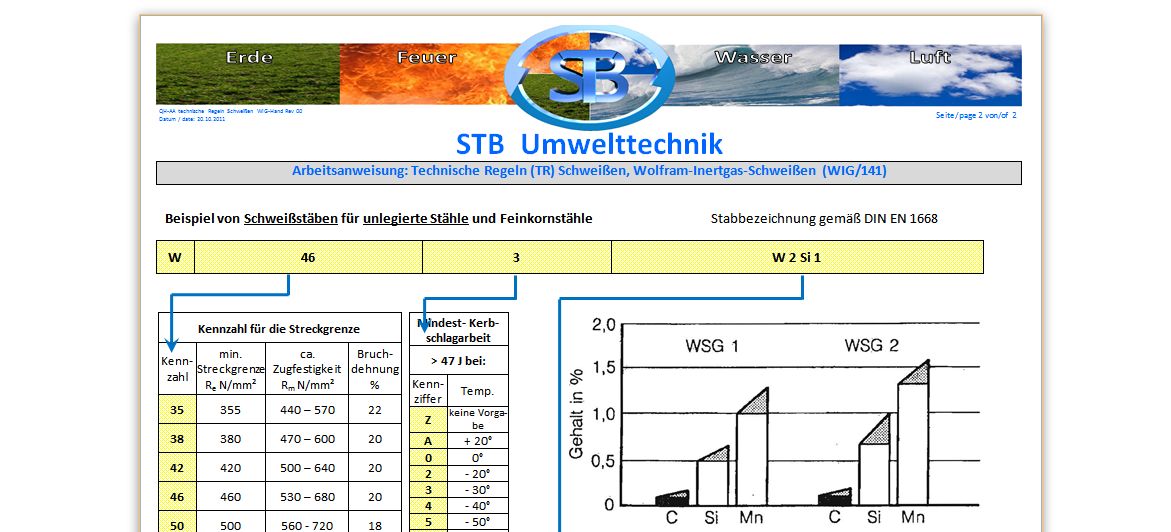

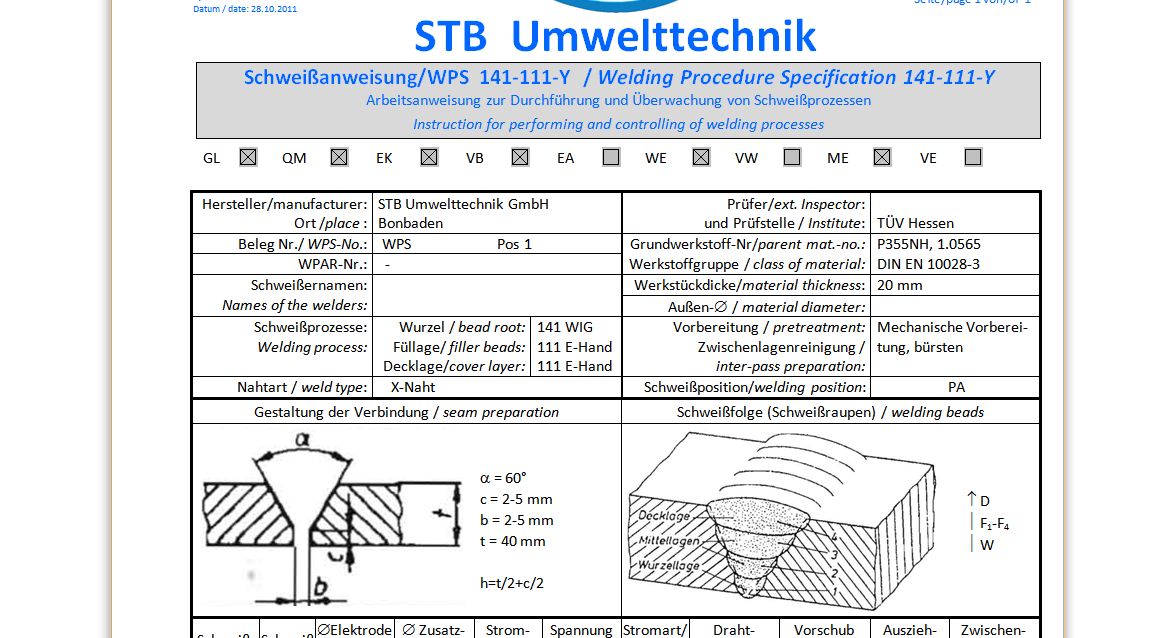

Since 2015 we additional have implemented a continous welding process inspection. Our welding engineer carries out a welding procedure sheet for all welding processes not only for subjects to acceptance.

Welding electrodes and welding wires are stored separately and unmistakeably sorted.

Heating tubes to warm-up the electrodes are available.

We also control and ensure T85-temperatures during the welding process.

We have welding procedure qualifications for all welding processes, which we carry out. We cooperate with TÜV/MOT and SLV Mannheim (Welding Training and Research Institute).

Application:

We offer the welding processes of WIG/TIG-welding, MIG/MAG-welding, MMA-welding and also robotized welding.

We process the following materials:

- Normal carbon steels, fine-grained steel, heat-resistant steels

- Aluminium and Aluminium alloys

- Standard stainless steels

- Austenitic stainles steels like 1.4539

- Duplex-stainless steels like 1.4462

- Nickel-base-alloys like Hastelloy, Incolloy, Monel

etc.

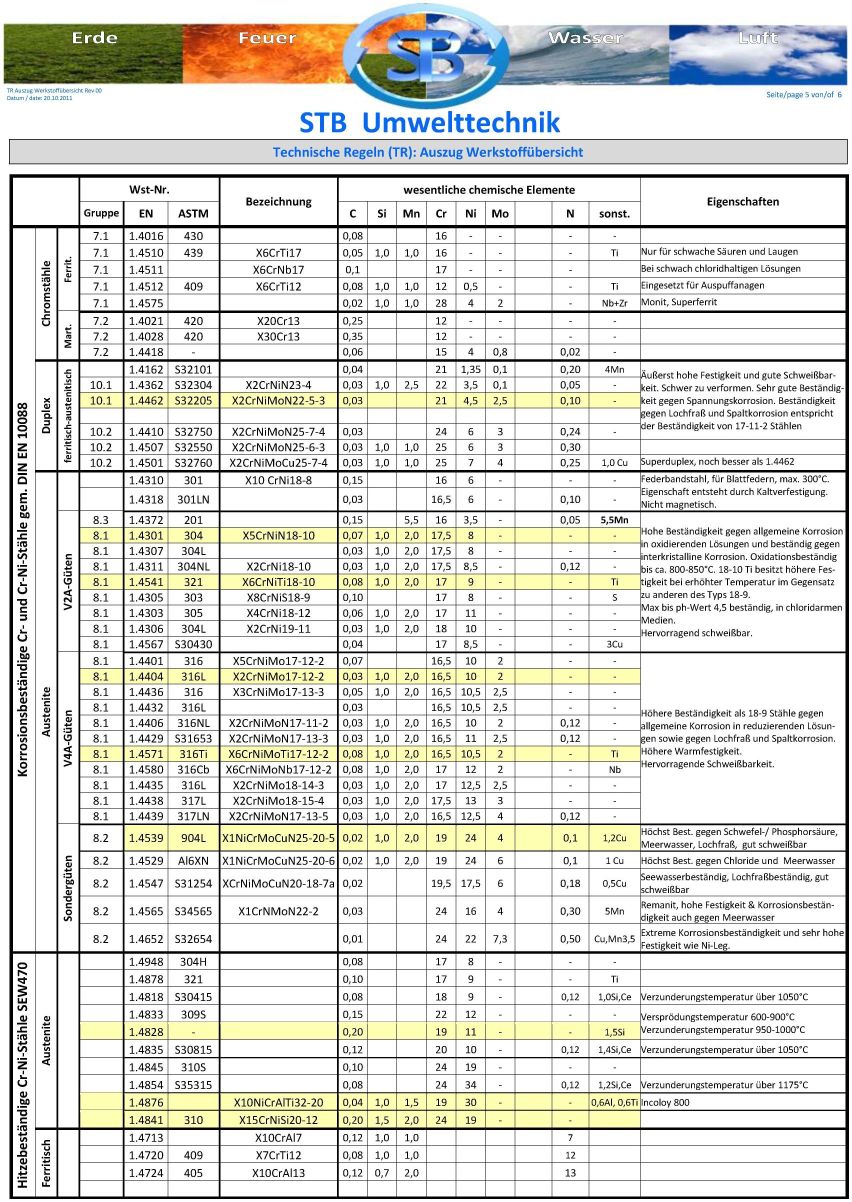

The following list gives an overview about the most common used stainless steel materials in our company.

English (UK)

English (UK)  Deutsch

Deutsch