Description:

We develop, construct, manufacture and deliver vertical agitators. These types of agitators are able to handle very big tank volumes. They generate huge energy inputs into the tank.

If these vertical agitators are not mounted at concrete bridges, we can also offer suitable steel bridges made by STB Umwelttechnik.

Application:

It is used in aeration and denitrification tanks, primary anaerobic tanks and for homogenisation of sludge liquor tanks .For an intensive mixing an for mixing-in of several liquids.

It can be used for max. diameters and edge lengths of 5,0 up to 35,0 m and a max. water depth of 2,5 up to 8,0 m and a tank capacity up to 6.000 m³ can be stirred with just one of these type of agitators.

Special Benefits:

- No or very little sediments on the tank bottom

- No air input and aerosol discharge through the surface

- Clam water surface

- Vortex-free recirculation

- On extra using pedestal necessary

- Individual design and optimised for different customer requirements

- Slowly turning mechanical agitator with drive in dry arrangement and vertical shaft

- Welded propeller with 2 or 3 blades for all diameters

- Radius formation adapted to circumferential speed

- Direct thorough mixing and homogenisation

- Propeller designed for gentle treatment of flock’s

- Designed like a ship screw

- Stable spur gear motor with housing in agitator design

- Installation and removal possible at filled tank

- No need for gear dismantling / installation to change oil

- Left-hand or right-hand rotation available, provided that the agitator is designed accordingly

The following material are available:

- Steel-galvanized or coated

- Typical stainless steels (s.s) like s.s. 304 or s.s. 316 / s.s. 316 Ti

- For special requirements we can even offer special materials like 1.4462, 1.4539 (Duplex) or even higher alloys like Hastelloy

The following options are available:

- R-V-SB= special floating sludge destroyer

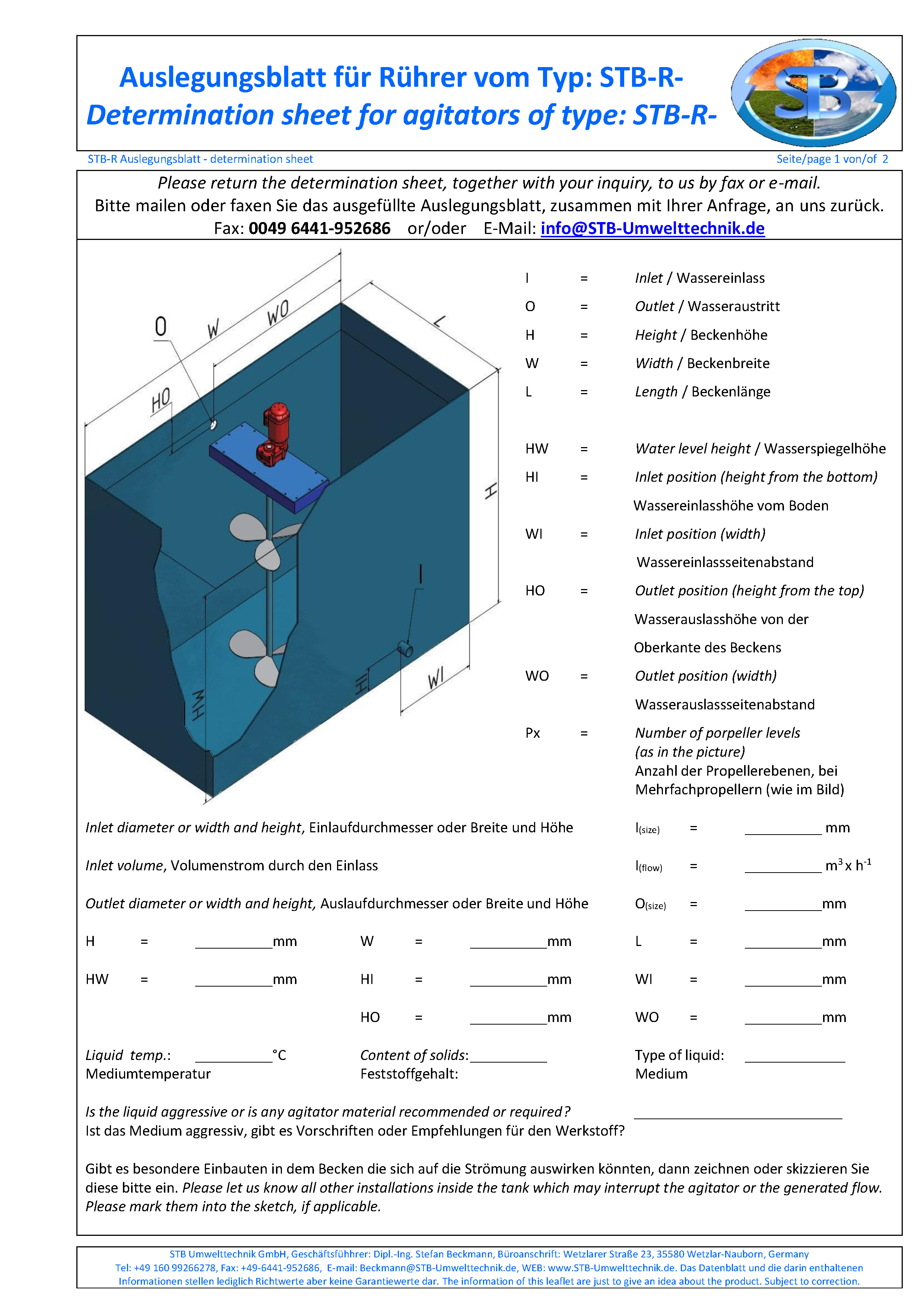

- R-V-X= number of propeller levels

English (UK)

English (UK)  Deutsch

Deutsch